TANRU

TANRU

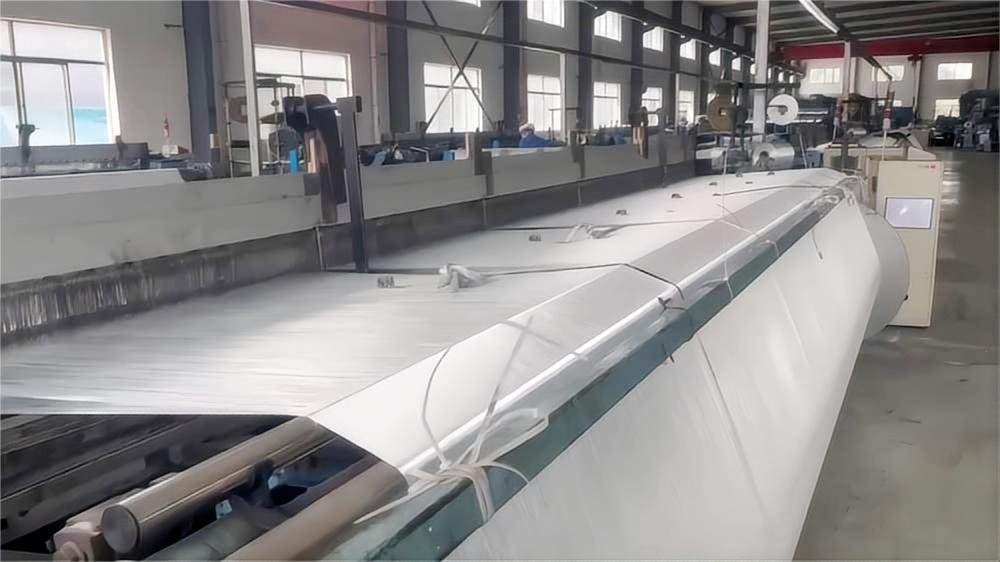

MultiFilament woven geotextile is composed of at least two parallel yarns (or flat yarns). One group is called warp yarn along the longitudinal direction of the loom (the direction in which the fabric travels), and the other group is arranged horizontally called weft yarn. The warp and weft are woven into cloth with different weaving equipment and processes, which can be woven into different thicknesses and densities according to different ranges of use. Generally, spinning geotextiles have relatively strong resistance in both vertical and horizontal directions. Tensile strength (latitude is greater than longitude), has good stability performance.

Filament woven is new geotextile, weft and warp crossly woven. Raw materials are PET filament, PP filament. Raw materials will be woven after being warped. Filament woven is high strength, low elongation, durability and anti-corrosion. It is structure stable with good engineering parameters and is widely used hydraulic engineering, coasts, roads, railways, wharfs, tunnels, bridges and other geotechnical engineering to fulfill the effect of reinforcement, isolation, anti-filter and protection.

Characteristics:

1. High strength: take high strength PP, PET or other synthetic fibers as raw materials, the integrated bearing capacity is improved after weaving.

2. Durable: the features of synthetic fibers are unmodified, undecomposed, and nonweathering, and keep its original property for long term.

3. Anti-corrosion: synthetic fibers are resistant to acid, alkali and bioerosion.

4. Water permeability: woven is adjustable to control its pore structure to reach certain permeability.

5. Easy transportation and storage: because of less weight, customized packaging, it is easy to transport, store and install.